top of page

AEROBIC BIOLOGICAL TREATMENT

UNI - BLOCK ™

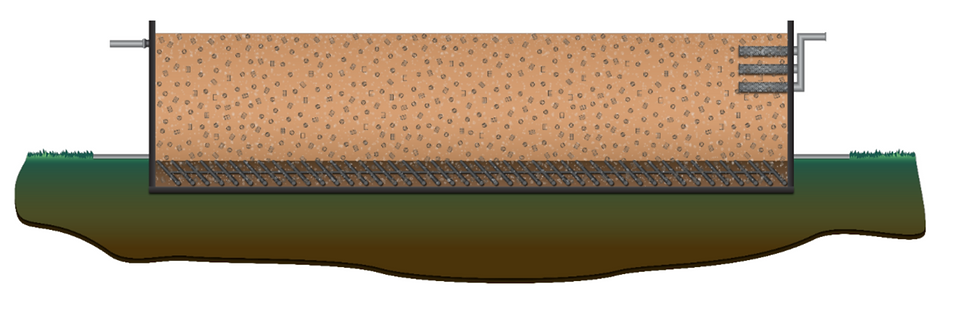

The UNI-BLOCK ™ is a highly efficient and compact system that integrates multiple treatment functions into a single tank. The UNI-BLOCK ™ has a rectangular shape, divided into 3 compartments that are interconnected by an opening in the common wall. Its compact design minimizes the space required for wastewater treatment, making it particularly suitable for facilities with limited land availability.

The process begins when influent wastewater enters the UNI-BLOCK ™, which is designed to accommodate varying flow rates and compositions. Here, the wastewater is subjected to aerobic biological treatment, where aerobic micro-organisms play a crucial role in breaking down the organic pollutants. The tank is equipped with aeration systems that introduce air or oxygen into the water, creating an oxygen-rich environment that supports the growth of bacteria. These micro-organisms thrive in the presence of oxygen, consuming the organic matter in the wastewater and converting it into biomass and biogas. The aeration also generates turbulence within the tank, ensuring that the microbial biomass remains in suspension and can continuously interact with the incoming wastewater.

From this first "active" compartment, the mixed liquor (mixture of active biomass and partly treated wastewater) flows by gravity via interconnecting windows in the common wall into the second, central, aerated and mixed compartment. In here, the same aerobic biological process takes place breaking down the residual organic pollutants and allowing the biomass to digest absorbed organics and convert it into CO2 and H2O and new biomass.

This compartment is also equipped with a large set of fine bubble diffusers installed at the bottom of the tank and fed with air from the "PD" blowers.

CHARACTERISTICS & ADVANTAGES

Single-tank design

Cost-effective

Combines biological treatment and sedimentation in one tank, divided into three interlinked compartments.

Lower construction and operational costs compared to conventional systems.

High process stability

Contionous operation with alternating treatment phases reduces load fluctuations.

Sequential operation

Each compartment cycles through aeration, settling, and decanting phases, allowing continuous flow.

Flexibility

Easily adaptable to varying flow rates and load conditions.

© ICR AMBIENTAL. ALL RIGHTS RESERVED.

© ICR AMBIENTAL. ALL RIGHTS RESERVED.

MEM - BLOCK ™ (MEMBRANE BIO REACTOR)

An MEM - BLOCK ™ MBR (Membrane Bio Reactor) works by combining traditional biological treatment with advanced membrane filtration to produce high-quality effluent. The biological treatment system will be composed of an aerobic zone and a membrane zone that will be subdivided into two compartments or tanks, usually called membrane trains.

The process begins with the biological treatment stage, where incoming wastewater is fed into an aeration tank. Air or oxygen is introduced into the tank to maintain aerobic conditions, allowing the micro-organisms to thrive and effectively digest pollutants. the activated sludge-wastewater mixture is intensively aerated and mixed by injection of a large amount of air supplying the necessary oxygen for the micro-organisms to convert all biodegradable organics into CO2 and water. The transfer of oxygen required by the microorganisms will take place in the fine bubble aeration reticles.

Unlike conventional activated sludge systems that rely on gravity-based sedimentation in secondary clarifiers to separate treated water from solids, the MBR process uses a membrane filtration system. This is the defining feature of MBRs. The mixed liquor from the aeration tank is passed through membranes - either microfiltration or ultrafiltration membranes —that physically block solids, bacteria, and other micro-organisms, allowing only clean water to pass through. These membranes ensure that particles larger than 0.1 microns are retained on the membrane surface and recirculated to the aerobic zone. This includes larger, particulate and soluble components of higher molecular weight, which are typically more difficult to biodegrade and therefore, keeping them in the biological system longer helps to improve the quality of the final effluent. The filtered water or permeate that passes through the membrane is a very high quality water that offers multiple possibilities for reuse.

The membranes can be arranged in two configurations. In submerged MBRs, the membranes are placed directly inside the bioreactor tank, submerged in the mixed liquor. In side-stream MBRs, the mixed liquor is pumped from the bioreactor to an external membrane unit, and the filtered water is then returned or discharged. Both configurations maintain high concentrations of biomass in the system, which boosts the efficiency of biological treatment and allows for a more compact plant design compared to traditional systems.

As the system operates, excess biomass or waste sludge gradually builds up and must be removed from the system to maintain balance. This sludge is typically sent to sludge treatment processes elsewhere in the plant.

© ICR AMBIENTAL. ALL RIGHTS RESERVED.

CHARACTERISTICS & ADVANTAGES

Compact

Reuse

Volume of the bioreactor is only 50% of that of a classic sludge reactor

Direct reuse of effluent possible for cleaning purpose, irrigation,...

Low maintenance

Unit has a maintenance friendly concept

Efficiency

Highly efficient separation system with submerged flatsheet ultrafiltration membranes

Quaternary

Direct quaternary treatment (reverse osmosis, nanofiltration)

Improved quality of effluent with lower COD and suspended solids concentration

Quality

Ion exchange

Ion exchange is possible. No need for a preliminary filtration step

MBBR (MOVING BED BIOFILM REACTOR)

An MBBR (Moving Bed Biofilm Reactor) unit is an advanced biological treatment process that uses small, lightweight plastic carriers, or biofilm media, which are freely suspended in the treatment tank. These carriers provide a large surface area for microorganisms to attach, and they are kept in constant motion through aeration or mechanical agitation. This ensures that the microorganisms growing on the carriers are exposed to the wastewater continuously, allowing them to effectively break down pollutants.

The process begins when influent wastewater enters the MBBR unit. Through intensive aeration, the used biofilm carriers are consistently floating around the whole unit. Aerobic bacteria attached to these biofilm carriers consume organic pollutants, such as biochemical oxygen demand (BOD) and chemical oxygen demand (COD), as well as nutrients like nitrogen and phosphorus in the wastewater. As wastewater flows through the reactor, microorganisms on the biofilm degrade these pollutants into simpler, harmless substances like water, carbon dioxide, and biomass.

As the biofilm grows on the carriers, older layers detach, naturally sloughing off to make space for new microbial growth. This constant turnover ensures that the biofilm does not get too thick or dense, which could otherwise hinder the system's efficiency. The movement of the biofilm carriers also minimizes the risk of clogging.

The treated effluent leaves the MBBR unit after passing through screens, which separate the effluent from the biofilm carriers. Though the wastewater may still contain some suspended solids and residual contaminants. To achieve the desired water quality.

© ICR AMBIENTAL. ALL RIGHTS RESERVED.

CHARACTERISTICS & ADVANTAGES

Compact design

Requires less space than conventinal activated sludge system

High surface area

Carries provide a large surface for microbial growth, enhancing biological activity

No clogging risk

Contionous movement of the carriers prevents fouling and blockages

Low maintenance

No need for sludge recycling or backwashing of media

Handles fluctuations in load and flow without impacting treatment efficiency

Stable operation

Easy integration

Can be added to existing plants to upgrade performance

bottom of page